Quick cutting tips

- Let the tool build pressure.

- Make 3 attempts to cut.

- Tool orientation can make the difference.

- Flip the tool upside-down.

Let the tool do the work is something many have heard of the years. One mistake that is made during cutting operations with hydraulic tools is not letting the tool build up the pressure. Below is a video of the B-Pillar of a 2014 BMW 330 being cut. A brand new cutter was being used and the operator needed to allow the pressure to build to complete the cut.

After allowing the pressure to build what if it doesn’t cut thru? You should always make 3 attempts to cut a pillar. The first cut is your plan A location. The second and third cuts are an inch or 2 higher and lower from the first cut. The body structure of late model vehicles have pillars that vary in thickness and reinforcements may not run the entire length of the pillars.

How do you attack the B-pillar with the cutters? One method is to completely open the blades up and cut perpendicular to the side of the vehicle. An alternative method is to limit the opening of the cutter blades and cut parallel with the side of the vehicle.

Last but not list. Let your imagination be your guide. Hydraulic tools can be used upside and held in almost any method as long as the operation never places themselves between the tool and the vehicle. So feel free to flip the tool upside down, hold it high or low!

Quick Tips

Motor City Monday Extrication Tip; Electric Vehicle Battery Pack Reinforcements

As vehicles change, our knowledge must continue to keep pace and expand our mental toolbox. The extrication tool manufacters have kept pace with their cutters, spreaders, and rams to combact these strong steels. It’s our job to stay

Electric Vehicle Battery Pack Reinforcements

Like everything in life, vehicles are changing, well vehicles keep changing. World leaders are pushing green vehicles which will increase our interactions with electric vehicles. First off, let’s look at the common acronyms of several common green and traditional vehicles.

- BEV = Battery Electric Vehicle

- PHEV = Plug-in Hybrid Electric Vehicle

- HEV = Hybrid Electric Vehicle

- ICE = Internal Combustion Engine

Unlike BEV, PHEV, and HEV, the term ICE refers to the engine itself, rather than the type of car. Normal/traditional gasoline and diesel cars have internal combustion engines.

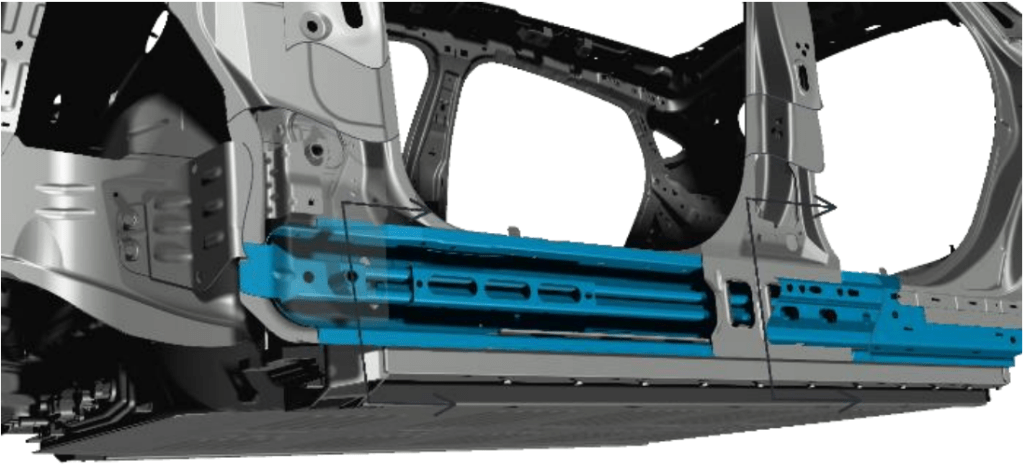

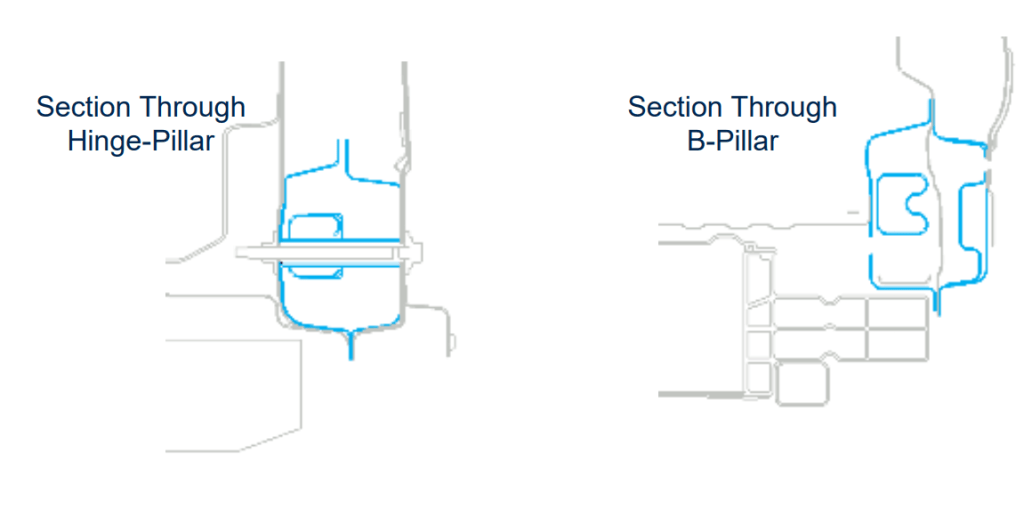

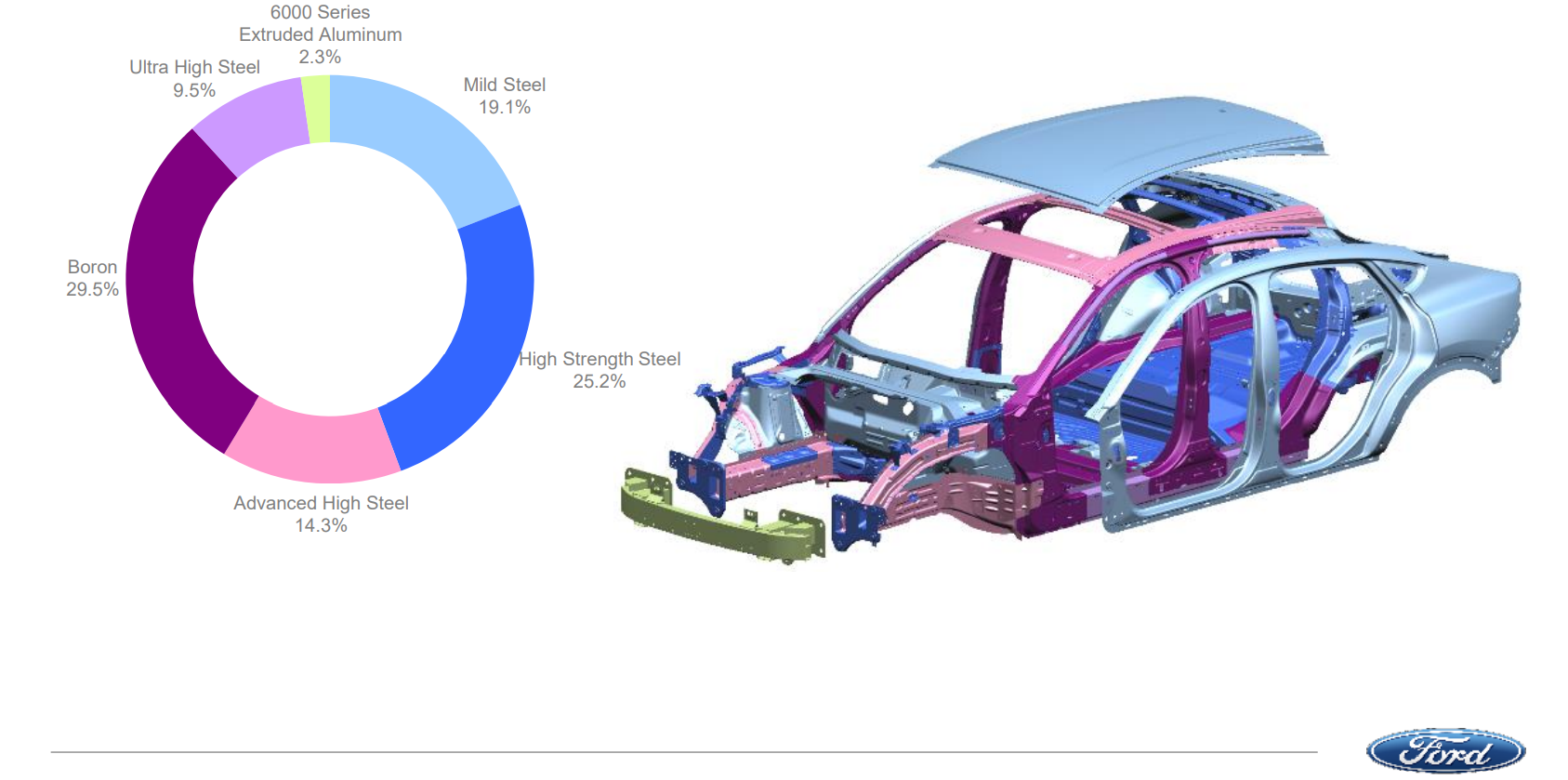

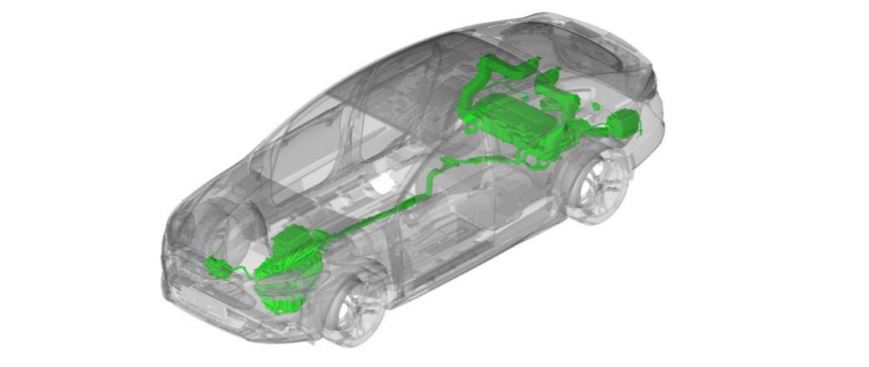

Electric Vehicles present several challenges to firefighters with battery fires leading the way. The automakers are designing and engineering extremely strong protective cages around battery packs. We are no strangers finding boron, martensite, and press hardened steels in the pillars, roof rails, and fender wells. However, in a BEV, the rocker panels and cross vehicle reinforcements will have boron and martensite steels to protect the battery pack from collisions that could comprise it. In the images below, the 2021 Ford Mustang Mach E has this strong steel in the rocker panels and cross vehicle reinforcements. The automakers can tie in the strong rocker panels into the front fender wells requiring us to make deep cuts during a dash lift or roll.

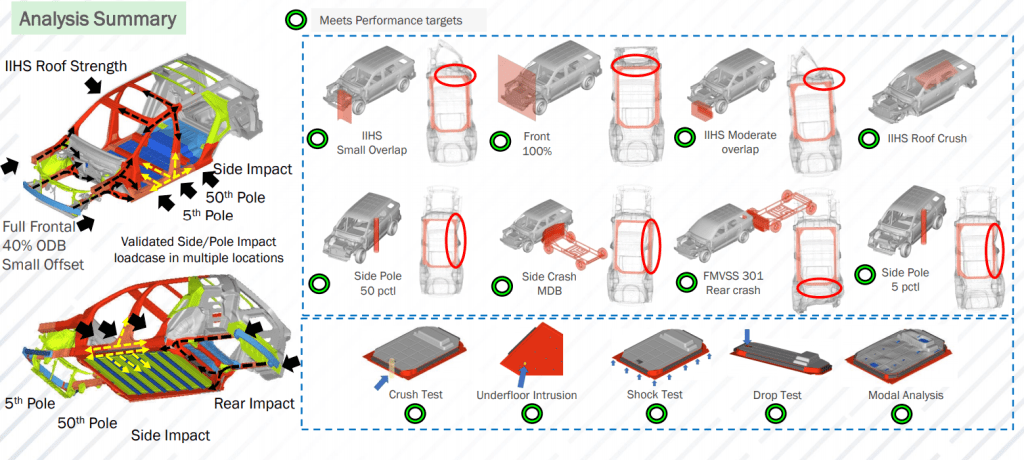

The image below shows the different testing vehicles are subjected to and a strong battery cage can not only protect the battery pack, but also the occupants of the vehicle.

As vehicles change, our knowledge must continue to keep pace and expand our mental toolbox. The extrication tool manufacturers have kept pace with their cutters, spreaders, and rams to combat these strong steels. It’s our job to stay current where the automakers are using strong steel.

Images from several Great Designs in Steel (GDIS) 2021 Presentations.

Quick Tips

A different spin on Cracking the Egg

Cracking the Egg has its’ share of fans and critics. Just remember training provides us with memory markers that we

Cracking the Egg

The technique known as “Cracking the Egg” is interesting to method to gain patient access of a roof resting vehicle. The video below from The Rescue Boss Facebook page replaces the cribbing that is normally used with a short Paratech strut. Watch how the strut pivots art the base plate as the rear of the vehicle is lifted.

Cracking the Egg has its’ share of fans and critics. Just remember training provides us with memory markers that we can draw from down the road and often use bits and pieces from different techniques during difficult or challenging rescues.

Quick Tips

Stabilization and Electric Vehicles

The battery weight and location are important considerations for stabilization.

One of the fastest methods of initial stabilization is to immobilize the vehicle by turning the 12-volt system OFF. Securing the ignition is accomplished by obtaining the key fob or keys and put them in a rescue apparatus Furthest away from the scene. Another quick, initial stabilization option are wheel chocks.

Chocks used during fire pumping operation are an excellent option. However, often a line is stretched off the apparatus and the engineer used the chocks on the apparatus. Many extrication teams use two wheel chicks tied together with a rope. Turtle Plastics has chicks that are lightweight and easy to deploy.

Chocks used during fire pumping operation are an excellent option. However, often a line is stretched off the apparatus and the engineer used the chocks on the apparatus. Many extrication teams use two wheel chicks tied together with a rope. Turtle Plastics has chicks that are lightweight and easy to deploy.

Stabilize the vehicle with cribbing, by removing air from the tires, or utilize the Lift Airbag Equipment for rescue.

Wheel chocks must match the size of the tires on the vehicle and used in pairs Tire size is designed to be proportional to the vehicle’s weight and size.

Three main factors affect the performance of wheel chocks:

- The angle of the road surface, called slope or grade. Parking on an angle greater than 10 degrees increases the risk of the car rolling off or over the chock.

- The size (height) of the wheel chock compared to the wheel height. Extra large wheel chocks are suitable for e.g. parked air craft where wind forces may come into effect.

- The surface slip or friction of the road surface, as the wheel chock may slide downhill due to wet grass or ice. Increasing the size of the wheel chock will not necessary allow the parking on inclines greater than 30% gradient (16.6 degrees).

- Keep in mind, the vehicle most likely will require full stabilization which should include cribbing and struts where necessary. Vehicles like a side resting vehicle or roof resting require struts to stabilize.